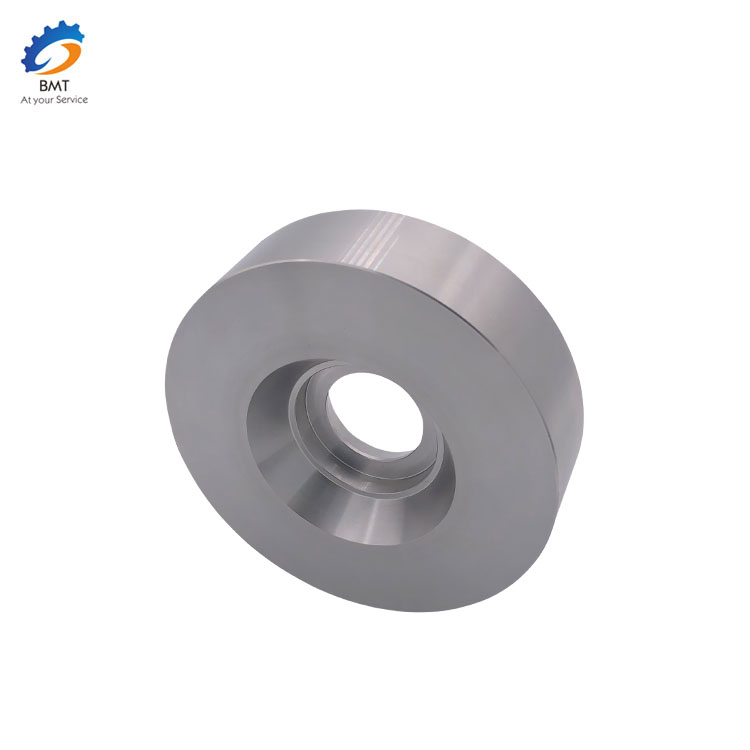

Fa'aleaganu'u CNC Milling Vaega Faumea

O le gaosiga o masini e masani lava o le faʻaogaina o le tusi lesona ma le faʻaogaina o le CNC e lua vaega. Fa'agaioiga tusilima e fa'atatau i le fa'agasologa o mea 'ese'ese e ala i le fa'agaioia fa'ata'ita'i o masini fa'ainisinia e pei o masini vili, lathes, masini vili ma masini va'a. Fa'agaioiina tusilima e talafeagai mo vaega laiti, gaosiga vaega faigofie.

Numerical machining machining (CNC) e fa'atatau i tagata faigaluega masini e fa'aogaina masini fa'atonu numera e fa'aauau ai le gaioiga, o nei mea fa'atonu numera e aofia ai le fa'aogaina o masini, fa'aliliu le nofoaga autu, masini tipi wedM, masini tipi filo ma isi. Ole tele ole a'oa'oga fa'agaioiga masini e fa'aogaina le fa'aogaina ole fa'aogaina ole numera. E ala i polokalame, o le mea faigaluega i le Cartesian faamaopoopo tulaga faamaopoopo tulaga tulaga (X, Y, Z) i le gagana polokalame, CNC masini meafaigaluega CNC pule e ala i le faailoagofieina ma le faamatalaina o le gagana polokalame e pulea le axis o le meafaigaluega masini CNC, otometi aveese. mea e tusa ai ma manaoga, ina ia maua ai le mea faigaluega faamaeaina. O le masini CNC e faʻagasolo le mea faigaluega i se auala faʻaauau, talafeagai mo le tele o vaega faʻalavelave faʻapitoa.

Le Tekinolosi Fa'agaioiga

CNC masini masini e mafai ona faʻapipiʻiina otometi e le CAD / CAM (Computer-aided design and Computer-aided Manufacturing) faiga i le faleoloa masini. O le geometry o vaega e otometi lava ona liua mai le CAD system i le CAM system, ma e filifilia e le tagata faigaluega masini auala eseese i luga o le mata faʻaaliga. Pe a filifilia e le tagata faigaluega masini se auala faʻaogaina, o le CAD / CAM system e mafai ona otometi lava ona faʻaalia le CNC code, e masani lava o le G code, ma faʻapipiʻi le code i totonu o le pule o le masini masini CNC mo le gaioiga moni o masini.

Meafaigaluega i tua o le falegaosimea, e pei o masini tipi uʻamea (e aofia ai le liliu, viliina, faʻapipiʻi, faʻaofiina ma isi meafaigaluega), pe afai o vaega o meafaigaluega e manaʻomia mo le gaosiga e malepelepe ma manaʻomia le toe faʻaleleia, e manaʻomia le auina atu i le faleoloa masini mo le toe faaleleia poʻo le gaosiga. Ina ia faʻamautinoa le lelei o le gaosiga, o le atinaʻe lautele o loʻo i ai se mafutaga faaleaoaoga masini, e nafa ma le tausiga o meafaigaluega gaosiga.